Our portfolio

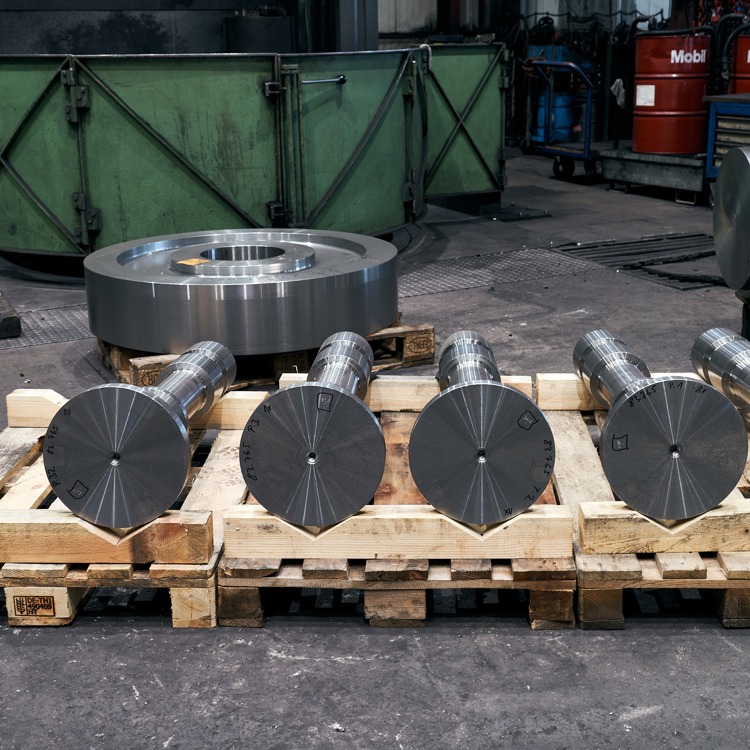

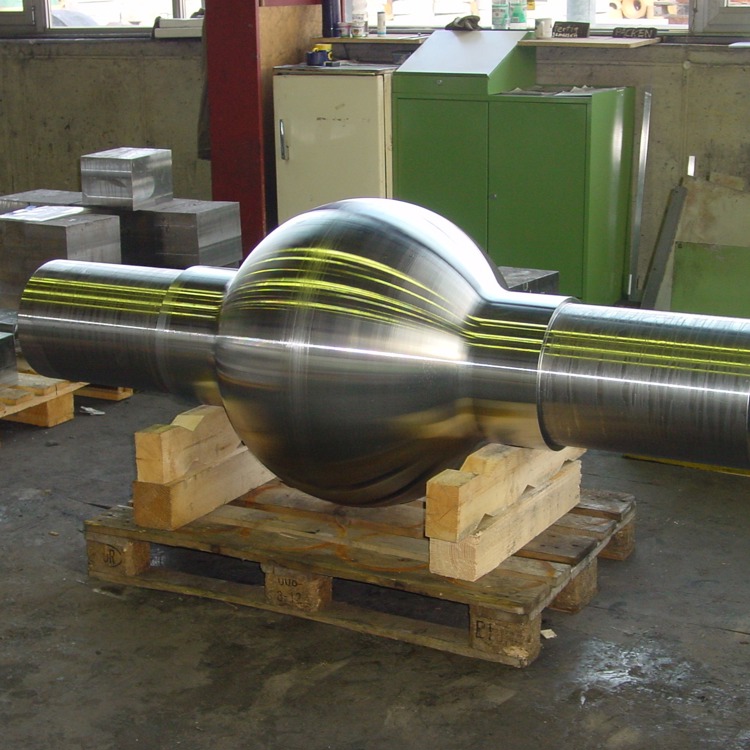

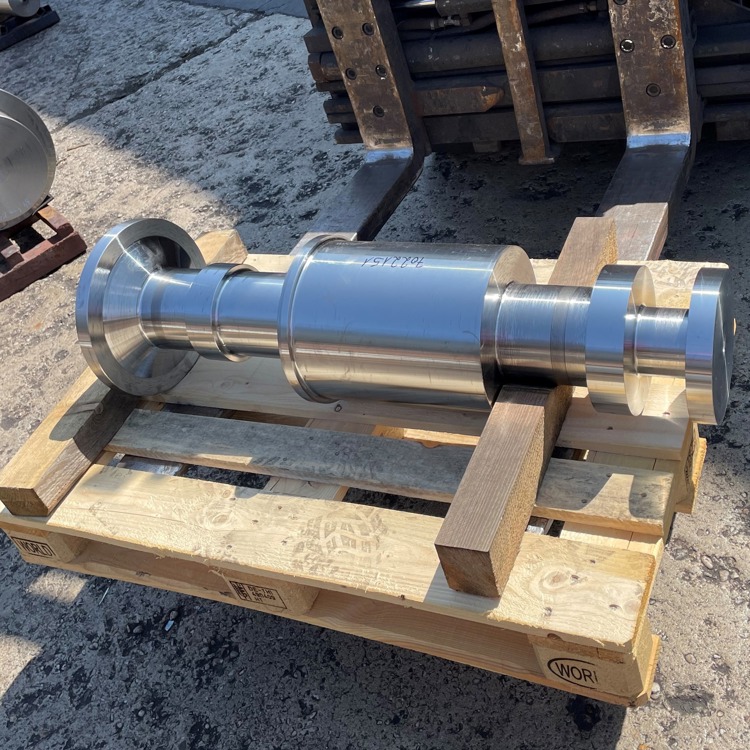

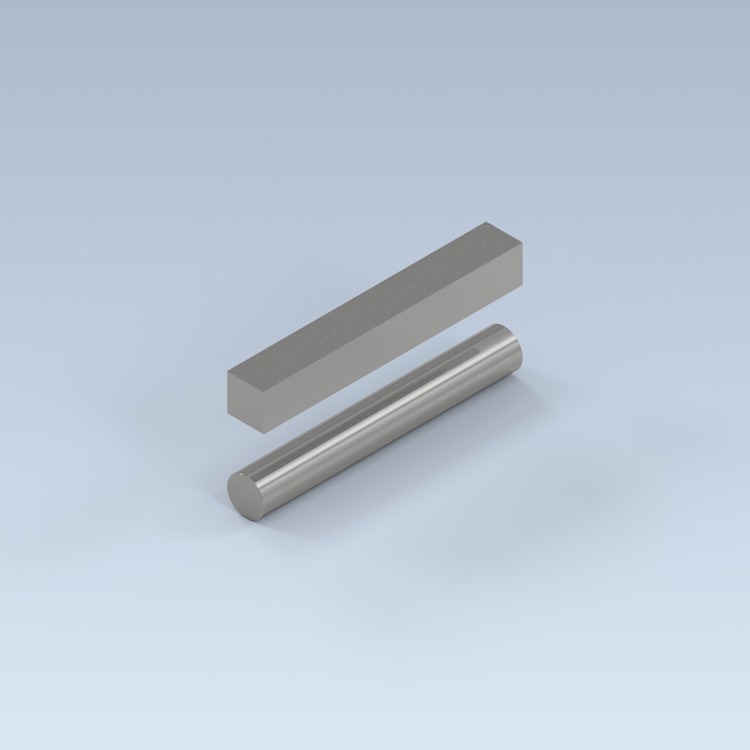

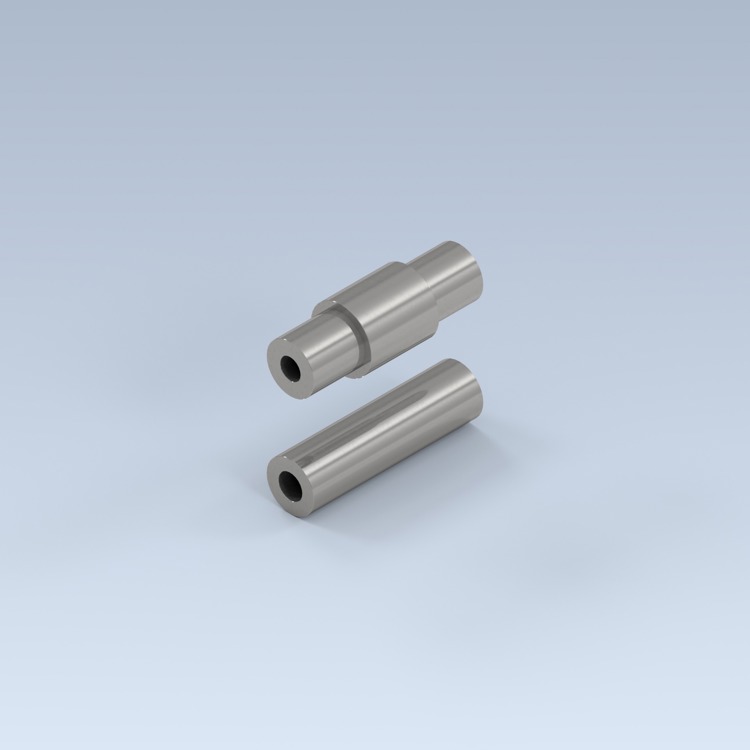

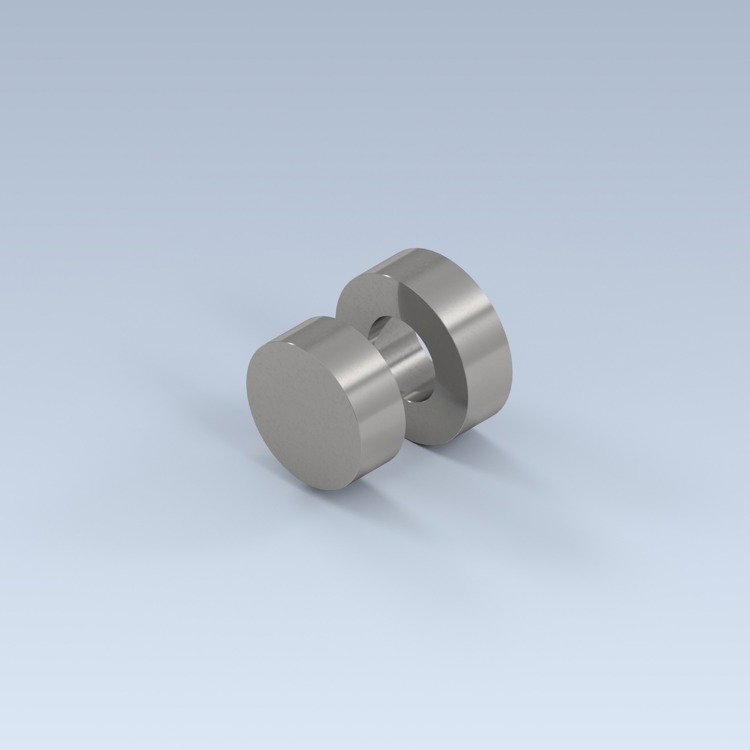

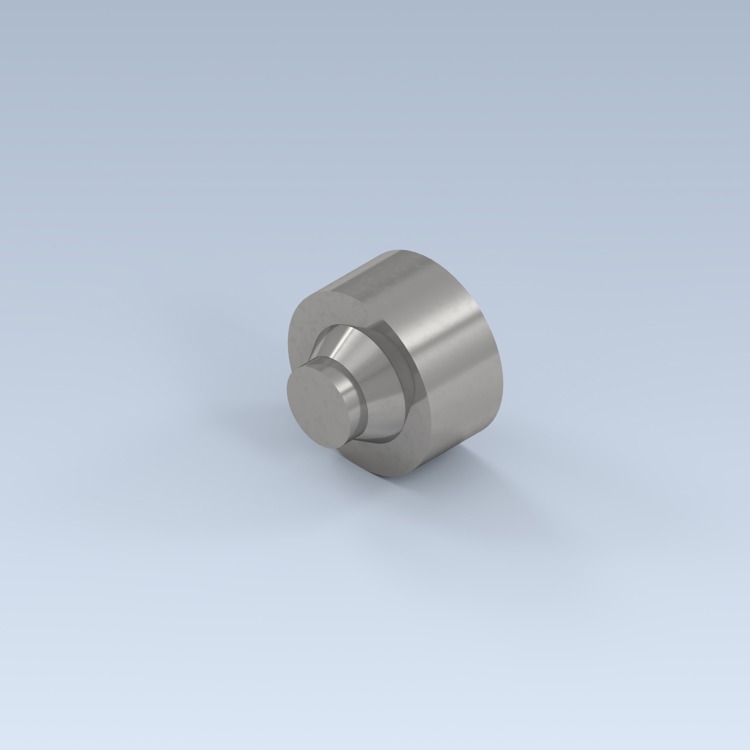

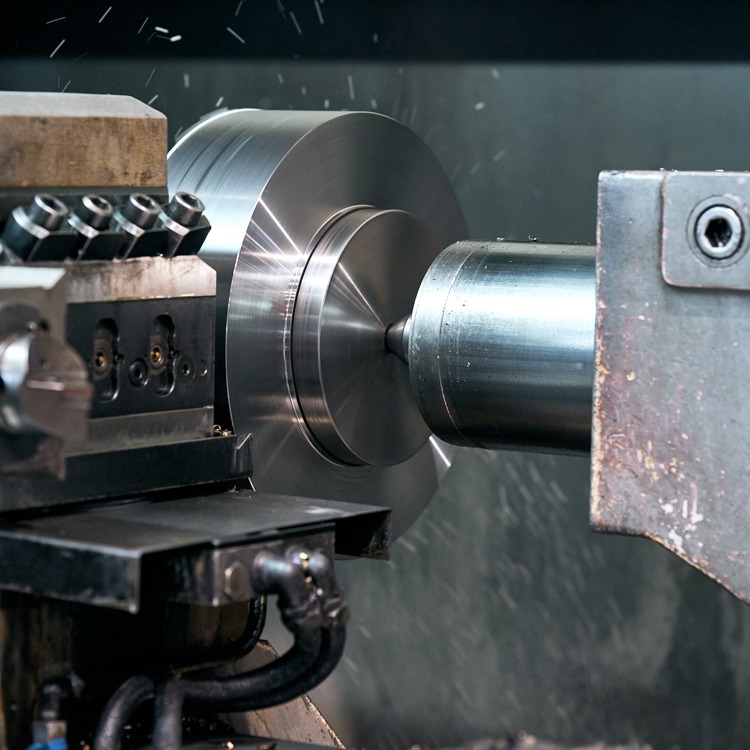

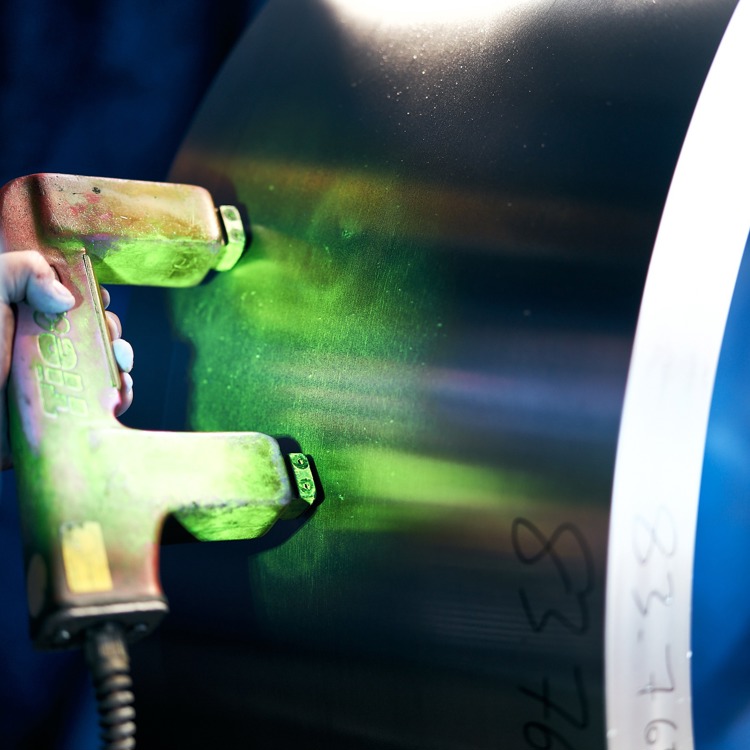

All the way from raw forgings to ready-to-install components, all the way from the idea to the innovation, we deliver results that precisely meet the customer’s requirements and wishes. Allow us to prove our competence, flexibility and reliability to you. The comprehensive possibilities of product testing at Hammerwerk Erft guarantee the reliable application of the most demanding forgings from a wide range of industries. Upon customer request, product tests are accompanied by various acceptance and commissioning services providers that fulfill the requirements and wishes of our customers 100%.

Our strength is individual consulting. Talk to one of our employees.

Prendre contact